BKM..HS Series Of Shaft Input High Efficiency Helical Hypoid Gearbox

Iinkcukacha zeMveliso

Ukuthembeka kubalulekile kuyo nayiphi na isethi yegiya, kwaye iiseti ze-hypoid ze-BKM ziyilelwe ukubonelela ngentsebenzo efanelekileyo ngexesha elongeziweyo. Izindlu zenziwe nge-alloy ye-aluminium ye-die-cast, eyaziwa ngamandla ayo kunye nokuqina. Olu lwakhiwo olunqabileyo luqinisekisa ukuba iyunithi yegiya inokumelana neemeko zokusebenza ezinzima kunye nokubonelela ngenkonzo ehlala ixesha elide.

Ukongeza kwiinkcukacha zobugcisa, iibhokisi zegiya ze-hypoid ze-BKM ziyilwe zinobuhlobo bomsebenzisi engqondweni. Iqinisekisa ukufakwa lula, ukugcinwa kunye nokusebenza, ukuvumela abathengi ukuba bagcine ixesha kunye nezibonelelo. Nokuba uyinjineli, igcisa okanye umqhubi, ukusebenzisa ezi yunithi zezixhobo kuya kuba ngamava angenaxhala.

Lilonke, iyunithi yegiya ye-BKM ye-hypoid sisisombululo esiguquguqukayo, esisebenza kakhulu kunye nesithembekileyo kwiinkqubo ezahlukeneyo zokuhambisa amandla. Ifumaneka kwiisayizi ezintandathu ezisisiseko, kunye noluhlu lwamandla okusebenza lwe-0.12-7.5kW, i-torque ephezulu ye-torque ye-1500Nm kunye ne-transmission ratio range ye-7.5-300, ezi yunithi zezixhobo zihambisa ukusebenza okugqwesileyo kunye nokusebenza kakuhle. Ngolwakhiwo olomeleleyo kunye noyilo olusebenziseka lula, iiyunithi zegiya ze-BKM ze-hypoid lukhetho lokuqala kumashishini ajonga izisombululo zokuhambisa amandla ezikumgangatho ophezulu.

Isicelo

1. Iirobhothi zoshishino, i-Industrial Automation, i-CNC yokuvelisa izixhobo zomatshini.

2. Ishishini lezonyango, ishishini leemoto, ushicilelo, ezolimo, ishishini lokutya, ubunjineli bokhuseleko lokusingqongileyo, i-warehouse logistics industry.

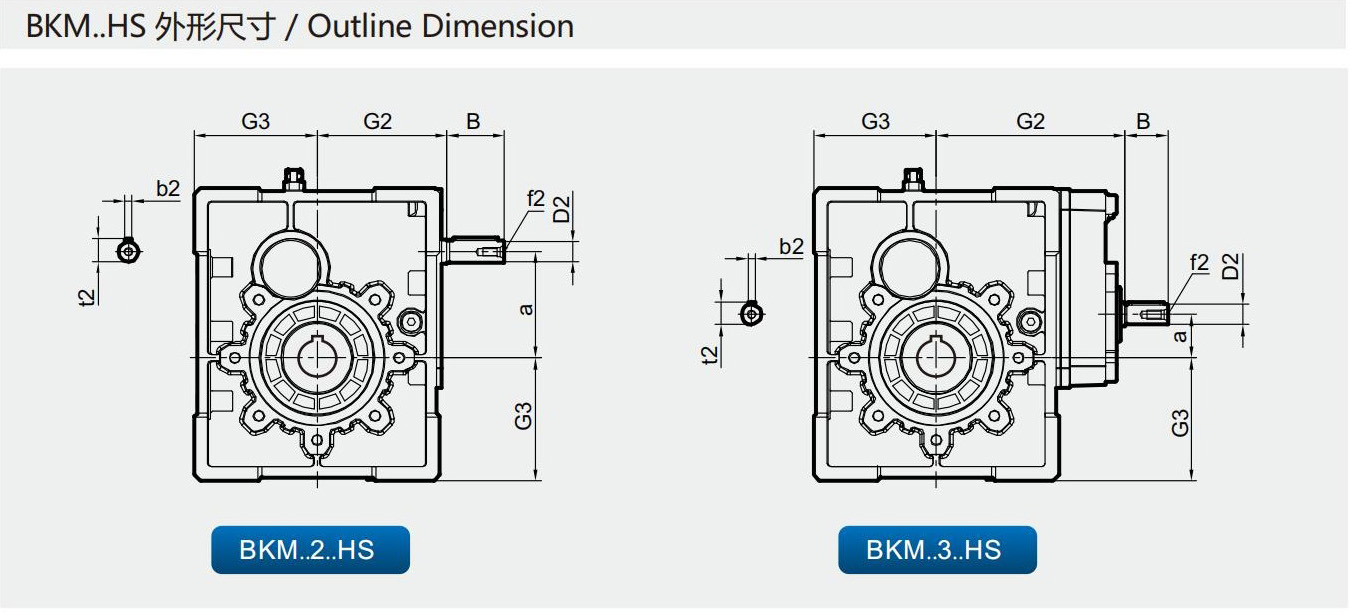

| BKM | B | D2j6 | G₂ | G₃ | a | b₂ | t₂ | f₂ |

| 0502 | 23 | 11 | 65 | 60 | 57 | 4 | 12.5 | - |

| 0503 | 23 | 11 | 100 | 60 | 21.5 | 4 | 12.5 | - |

| 0632 | 30 | 14 | 76 | 72 | 64.5 | 5 | 16 | M6 |

| 0633 | 23 | 11 | 111 | 72 | 29 | 4 | 12.5 | - |

| 0752 | 40 | 16 | 91 | 86 | 74.34 | 5 | 18 | M6 |

| 0753 | 30 | 14 | 132 | 86 | 30.34 | 5 | 16 | M6 |

| 0902 | 40 | 19 | 107 | 103 | 88 | 6 | 21.5 | M6 |

| 0903 | 30 | 14 | 146 | 103 | 44 | 5 | 16 | M6 |

| 1102 | 50 | 24 | 165 | 127.5 | 107 | 8 | 27 | M8 |

| 1103 | 40 | 19 | 256 | 127.5 | 51 | 6 | 21.5 | M6 |

| 1302 | 60 | 28 | 171.5 | 146.5 | 123 | 8 | 31 | M10 |

| 1303 | 40 | 19 | 262 | 146.5 | 67 | 6 | 21.5 | M6 |